Flexible Cables And Multi Core Cable

Home Products Flexible Cables And Multi Core Cable

Master Flex manufacture high quality cables according to IS : 694 : 1990 for house hold and industrial lightening purpose . We never compromise to use sub-standard raw material instead of high standard & hence Master Flex consistently remain with the high degree of quality. These cables are suitable for fixed wiring, flexible operation & for use on AC single phase systems for rated voltage up to and including 1100 Volts. These cables can be used on DC systems for rated voltage up to & including 1500 Volts to earth.

CONSTRUCTION DETAILS

Flexible Cables CONDUCTOR : Solid / Stranded / Multistranded high conductivity annealed copper wires to meet the requirements according to IS : 8130 : 1984. Copper gets corrode in the atmosphere where sulphur fumes are present, in such conditions Tinned Copper should be used.

INSULATION :

TYPE A Elastomer PVC suitable to withstand maximum rated continuous operating temperature upto 70°C of conductor & the rated voltage upto and including 1100 Volts.

TYPE B Insulation suitable to withstand maximum rated continuous operating temperature upto 70°C of conductor & the rated voltage above 1100Volts.

TYPE C Heat resisting compound for maximum rated conductor temperature 85°C to the rated voltage upto & including 1100, Volts.

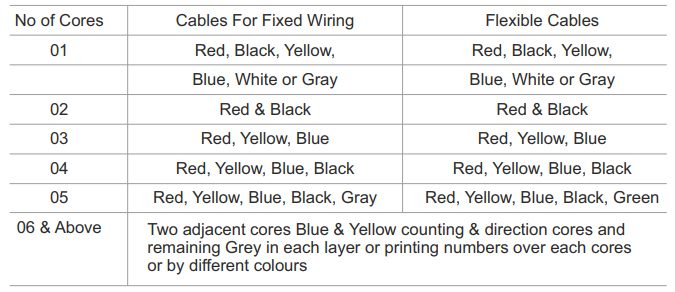

CORE IDENTIFICATIONS :

Insulation colour are in accordance with IS : 694 : 2010 specification, as under :

LAYING UP :

LAYING UP : In case of Multicore cables, cores are laid up with suitable equidistance lay at right hand side direction.

SHEATH : The over coating of PVC over the single core insulated wire or multicore laid up wires is called the sheath. The compound should be as per IS : 5831 : 1984 but dimension should be according to IS : 694 : 2010. We consider the customer requirement according to their special use

|